- Color Education

-

-

Color Knowledge

-

Current position:Home > Color Knowledge

-

How to measure the colour of coffee?

-

Coffee is one of the most consumed beverages worldwide with over 400 billion cups being drunk every year. With the quality of instant coffee needing to keep up with its freshly brewed counterpart, every aspect of these drink granules need to be as good as they can possibly be to keep instant coffee popularity rising.

Why are we analyzing appearance?

When completing any analysis of colour and appearance it is important to know from the start why measurements are being taken. Are customers claiming a difference in colour and therefore consistence? Are samples of coffee being compared to the products of factories in different locations to ensure consistency as a brand? Is the data being used to ensure top quality products over time? Is the data being used for research and development processes? Whatever the reason for colour measurement, the methodology should suit the needs of the customer and work well within the production processes.

How many measurements?

The amount of measurements taken is dependent on the time available for testing, how much sample is available for testing, how accurate the data needs to be and what instrument is being used for testing. Generally speaking, the more measurements taken, the better the data received represents the batch of product as a whole. For samples of irregular appearance, data taken over a number of samples combined to form an average is a more precise method for data analysis.

How much sample?

Similarly to how many measurements are needed, the more sample tested the better. An ideal method is to calculate an average using the data collected. A sample of the product should be measured then, depending on how much sample is available, the sample should be replaced with more from the same batch or turned to provide a different surface to measure. The main aim of this is to give a broader view of the batch being produced; this can be repeated as many times as required.

When to measure

Most production processes, whilst very similar across the industry, are naturally modified to inpidual manufacturers in keeping with specific recipes or methods of production. For the majority, there are a few stages in which colour can be measured, depending on the amount of time available for evaluating quality and also the instrument being used and its capabilities.

Right at the start of production, the coffee beans themselves can be measured. To produce instant coffee, it takes a lot of time and money and, if the beans are not right from the start, the finished product cannot be expected to be as good as it should at the end. Measuring the beans can give an idea as to what will produce a good product at the end without having to waste time and money processing them. After roasting is another good time to measure the colour of the bean as colour can be a key indicator of an error in the cooking process. If the beans are too dark then it could be the result of over-heating. If the beans are too light then it will be evident that they haven’t been cooked enough.

To produce instant coffee, commonly the granules are freeze-dried. Similarly to measuring after roasting, appearance analysis can indicate an issue with the drying process. It is always a safer option to analyse a sample after any alteration to the product takes place to make sure all samples are reacting as they should and are appearing the same after the processes.

At the very least, a sample should be measured before the product is packaged ready for shipping. Taking a measurement at this stage acts as a final check to make sure no substandard product leaves the factory.

What data should be analysed

To have as much relevant data as possible, measuring with either Hunter L, a, b or CIE L*, a*, b* can give a detailed idea as to the colour of the sample. For more detail, the HCCI (Hunterlab Coffee Colour Index) can be used or the sample compared to SCAA (Specialty Coffee Association of America) standards. When using software, many more indices can be used to gather as much in depth data as is required.

Tool for the Job

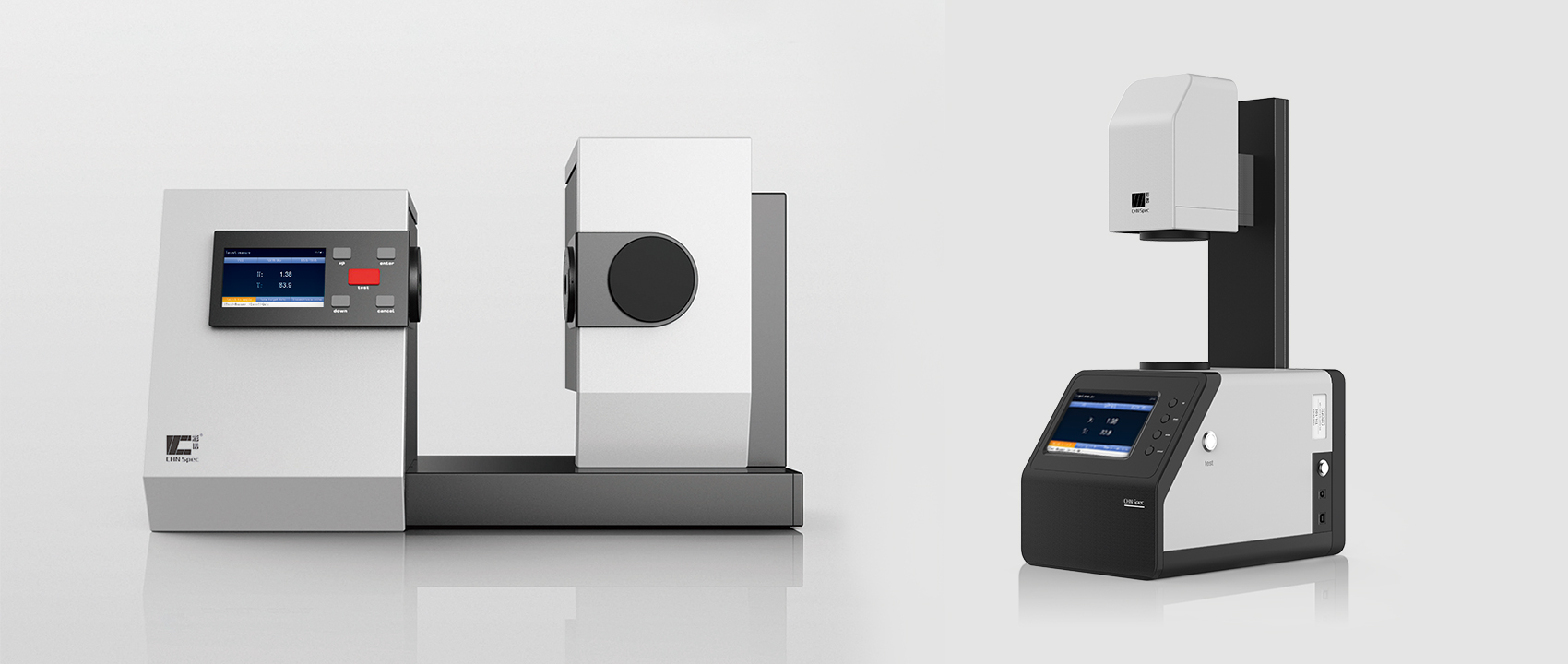

The main options available for coffee analysis would be to use either a Colorimeter or Colorimetric Spectrophotometer, but which one? A tristimulus colorimeter can measure colour and the technology is built with the older optical filter design. A Colorimetric Spectrophotometer, on the other hand, carries out colour measurement avoiding the variation of the optical filters and provides a far more detailed analysis of colour by, in this case, obtaining accurate reflectance colour data over the visible spectrum. Its reliability of measurements for longer periods of time make it an ideal tool when measuring a mass produced product for public consumption.

A Spectrophotometer should be used that is capable of measuring and acquiring data of solid, liquid, semi-solid and powder samples. The ability to measure samples in these different states can allow for a more detailed quality control process as analysis can be taken at the varying points throughout production listed above as well as during circumstances inpidual to a manufacturer.